To fully understand the challenges of recycling composite and complex materials, it is crucial to define what is meant by these terms.

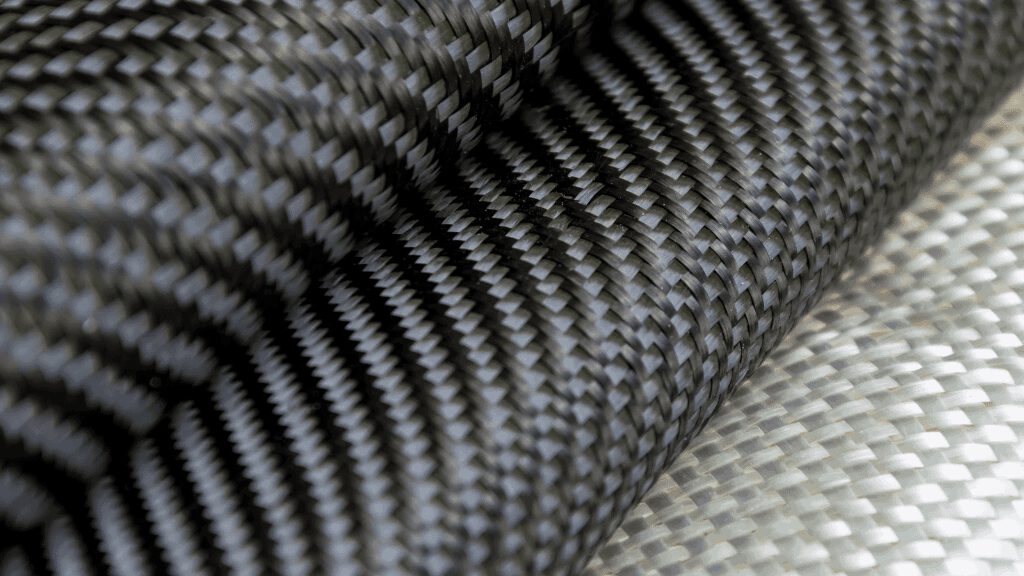

Composite materials consist of two or more distinct materials that, when combined, produce a material with superior properties. Typically, a composite material includes a reinforcing matrix and phase, such as glass or carbon fibers immersed in a polymer resin.

Complex materials, on the other hand, can include any combination of materials that, due to their structure or chemical composition, require special treatments for recycling. These materials can be found in electronic equipment, vehicles, building structures, and many other everyday products.

What are the constituent elements of a composite material

The building blocks of a composite material vary depending on the specific application and desired properties. The main component is the matrix, which can be polymeric, metallic, or ceramic in nature.

The matrix serves to keep the reinforcing fibers together, distributing the loads and protecting the fibers from external agents.

Reinforcement fibers are the other fundamental element and can be made of materials such as glass, carbon, Kevlar or other synthetic fibers.

These fibers give the composite strength and rigidity. Other additives and fillers may be included to improve specific properties of the composite, such as fire resistance or electrical conductivity.

The recycling of composite and complex materials is a key challenge in modern waste management.

With the increased use of these materials in numerous industries, it is crucial to understand how to properly manage them to reduce environmental impact. Composite materials, which consist of two or more components with different properties, offer significant advantages in terms of strength and lightness.

However, their structural complexity makes recycling a complicated process that requires advanced technologies and innovative strategies.

This guide aims to provide a detailed overview of current and future methodologies for the recycling of composite and complex materials, illustrating the most effective challenges and solutions.

We will explore various aspects of the recycling process, from waste management to the implementation of advanced techniques, to better understand the very nature of these materials.

Recycling of composite materials

Recycling composite materials is a process that requires advanced technologies and in-depth knowledge of the properties of the materials themselves. Composites, which are mainly used in aerospace, automotive, and construction, are difficult to recycle due to their heterogeneous composition. Traditionally, recycling these materials involves mechanical grinding, but this is not always effective in completely separating components.

Recently, more sophisticated techniques, such as thermal and chemical recycling, are being developed.

Thermal recycling involves the use of heat to decompose materials, while chemical recycling uses specific solvents to dissolve resins and separate fibers.

These methodologies, while promising, require further improvements to become economically viable at scale.

Complex waste management

Complex waste management is a significant challenge in the context of environmental sustainability. Complex wastes include composite materials and other wastes that are difficult to treat due to their variable composition and the presence of hazardous substances.

Effective management requires accurate classification and specific treatment for each type of waste.

Management strategies include reduction at source, reuse, recycling and energy recovery. Reducing the production of complex waste at source is the first step, followed by the reuse of materials whenever possible. Recycling, as described above, is crucial, but it is often not enough.

In some cases, energy recovery through controlled incineration can be an effective, although not without controversy.

Efficient recycling

Efficient recycling of composite and complex materials requires the adoption of advanced technologies and integrated waste management.

Automated separation techniques, such as optical recognition and electrostatic separation, are crucial tools for improving recycling efficiency.

These technologies make it possible to identify and separate materials more precisely, reducing operating costs and improving the quality of recycled materials.

Additionally, implementing extended producer responsibility (EPR) policies can incentivize companies to design products that are easier to recycle.

These policies require manufacturers to be responsible for managing the end-of-life of their products, promoting eco-design and the use of recyclable materials.

Regulations involved

The regulations involved in the recycling of composite and complex materials are crucial to ensure that the process takes place in a safe, effective and environmentally friendly manner.

These regulations can vary nationally and internationally, and include specific regulations for waste management, environmental protection, and worker health and safety. Here are some of the main standards and directives governing the recycling of these materials:

Normative Internazionali

- European Waste Directive (2008/98/EC as amended)

- This directive establishes the legal framework for waste management in the European Union. It promotes the reuse and recycling of materials and introduces the principle of extended producer responsibility (EPR).

- End-of-Life Vehicles Directive (2000/53/EC as amended)

- This directive specifies requirements for the treatment and recycling of end-of-life vehicles, including composite materials used in automotive components.

- REACH Regulation (1907/2006 as amended)

- REACH concerns the registration, evaluation, authorisation and restriction of chemicals. It imposes restrictions on the use of certain substances in composite materials, indirectly affecting recycling processes.

National regulations

- Legislative Decree 152/2006 s.m.i.

- Known as the Consolidated Environmental Act, this legislative decree regulates waste management and establishes rules for the treatment and recycling of materials.

- UNI EN 13430 standard

- This Italian standard specifies the requirements for packaging recoverable through the recycling of materials, which is also applicable to composites used in packaging.

- Technical Standards for Waste Management (Ministerial Decree of 5 February 1998 as amended)

- It establishes the technical criteria for the management and recovery of waste, including composite materials.

Industry regulations

- ISO 14001 Standards

- ISO 14001 certification concerns environmental management systems. Companies that recycle composite materials often adopt this standard to demonstrate their commitment to environmentally sustainable practices.

- ISO 9001 Standards

- Although not specifically for recycling, ISO 9001 standards for quality management are often adopted by companies to ensure that their recycling processes meet high quality standards.

Safety Regulations

- Seveso III Directive (2012/18/EU)

- This Directive concerns the control of major-accident hazards involving certain dangerous substances and applies to recycling facilities that process composite materials containing hazardous chemicals.

- CLP Regulation (1272/2008)

- The Classification, Labelling and Packaging of Chemical Substances and Mixtures (CLP) Regulation affects the management of composite materials that contain hazardous chemicals.

- ISO 45001 Standards

- Certification according to the UNI ISO 45001 standard ensures the reduction of the number of accidents, near misses and occupational diseases, helping to minimize the social and economic costs of non-safety, and making the production system more efficient. It also promotes greater efficiency of internal processes, also through integration with other management systems, those for quality (UNI EN ISO 9001) and environmental (UNI EN ISO 14001).

Innovations in recycling

Innovations in the recycling of composite and complex materials are opening up new possibilities for sustainable waste management. Among the emerging technologies, recycling through enzymatic processes is particularly promising. This approach uses specific enzymes to decompose polymer resins, allowing fiber separation and recovery in a more efficient and less polluting way than traditional methods.

Another significant innovation is the use of self-healing materials, which can repair damage sustained during the product’s life cycle, extending its lifespan and reducing the need for recycling. These materials, which are still under development, could revolutionise the composites industry, making waste management more sustainable.

Concrete examples of composite and complex materials

Composite and complex materials are widely used in various industries due to their unique properties.

Here are some concrete examples of these materials and their applications.

Composite materials

- Polymer Reinforced Carbon Fiber (CFRP)

Description: CFRP is made from carbon fibers immersed in a polymer resin matrix.

Applications: It is used in the aerospace, automotive, marine and sports sectors due to its high strength and light weight.

Advantages: Tensile strength, light weight, high rigidity.

Challenges in Recycling: The separation of carbon fibers from the polymer matrix requires advanced technologies such as pyrolysis.

- Polymer Reinforced Fiberglass (GFRP)

Description: GFRP is composed of glass fibers immersed in a polymer resin matrix.

Applications: Used in construction, wind turbines, marine and industrial applications.

Advantages: Corrosion resistance, good strength-to-weight ratio.

Challenges in Recycling: Mechanical grinding is often used, but it can be inefficient in separating components.

- Polymer-reinforced Kevlar

Description: Composed of Kevlar fibers immersed in a resin matrix.

Applications: Bulletproof vests, helmets, automotive and aerospace structures.

Advantages: High tensile strength and impact strength, light weight.

Challenges in Recycling: Thermal decomposition and chemical separation of fibers are complex and expensive.

Complex Materials

- Sandwich Panels

Description: Sandwich panels consist of two layers of rigid materials separated by a lightweight but strong core, often made of foam or honeycomb.

Applications: Used in construction, aerospace and transportation for thermal and structural insulation.

Advantages: Lightness, thermal insulation, high structural resistance.

Challenges in Recycling: The separation of layers and core requires complex mechanical and chemical processes.

- Printed Circuit Boards (PCBs)

Description: PCBs are made up of various layers of conductive and insulating materials, usually copper and epoxy resin.

Applications: Used in electronics, computers, mobile phones, and electronic devices.

Advantages: High density of components, reliability.

Challenges in Recycling: Recovery of precious metals and separation of plastic materials require electrochemical processes and pyrolysis.

- Metal Matrix Composites (MMC)

Description: Composites consisting of a metal matrix reinforced with ceramic particles or fibers.

Applications: Used in high-temperature applications, such as gas turbines and automotive components.

Advantages: High temperature resistance, improved wear resistance.

Challenges in Recycling: Separating ceramic fibers from the metal matrix is difficult and often requires advanced thermal processes.

Conclusions

Composite and complex materials offer significant advantages in terms of performance and versatility, but they also present significant challenges in recycling. Advanced technologies and innovations in the industry are crucial to overcoming these challenges, promoting sustainability and efficiency in waste management.

To book a collection, rely on a specialized company such as Valli Gestioni Ambientali.